Mining companies are exploring microbially mediated processes such as bioleaching for critical...

Microbially Mediated Mineral Recovery from Coal Ash

In the mining industry, strategies that leverage microbial processes are increasingly attractive as sustainable and cost-effective methods for improving the recovery efficiency of precious metals from low grade ores. A similar approach can be used to recover minerals from waste streams generated by other industries. For example, coal-fired power plants produce a high volume of coal combustion residuals that must be properly managed, or their release can result in substantial environmental contamination. Treatment processes that include the recovery of valuable minerals from coal fly ash can reduce the costs and environmental risks associated with landfill disposal while providing a new revenue stream and domestic source for critical minerals.

Coal Fly Ash as a Valuable Alternative Source for Critical Minerals

The United States’ critical minerals list includes minerals and rare earth elements (REE) that are essential to one or more modern technologies and are vulnerable to supply chain disruption. To safeguard the economic and national security of the United States, unconventional and secondary domestic sources of critical minerals are needed to decrease reliance on importing these resources. In 2020, the Department of Energy created the Carbon Ore, Rare Earth and Critical Minerals (CORE-CM) Initiative for U.S. Basins for this purpose, and the use of coal by-products and waste streams as domestic sources of critical minerals was specifically listed as a focus.

The United States’ critical minerals list includes minerals and rare earth elements (REE) that are essential to one or more modern technologies and are vulnerable to supply chain disruption. To safeguard the economic and national security of the United States, unconventional and secondary domestic sources of critical minerals are needed to decrease reliance on importing these resources. In 2020, the Department of Energy created the Carbon Ore, Rare Earth and Critical Minerals (CORE-CM) Initiative for U.S. Basins for this purpose, and the use of coal by-products and waste streams as domestic sources of critical minerals was specifically listed as a focus.

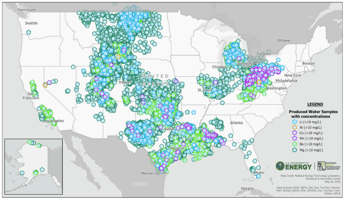

Even as there has been a reduction in coal production over the last decade, coal-fired power plants still produce

substantial amounts of coal fly ash each year. Also, large coal ash reserves in landfills and containment ponds remain accessible and represent an additional supply that can be utilized. Reedy et al. (2024) estimates that the potential value of extractable lanthanide REEs in accessible ash produced in the United States between 1950-2021 is ~$8.4 billion. When adding in the potential value of recoverable yttrium and scandium, the estimate increases to ~$97 billion1. Investing in technologies to reuse this waste stream has the potential to enhance the United States’ energy security, support advanced technologies, provide local economic opportunities, and help mitigate the environmental risks of coal fly ash containment.

Microbial Solutions for Mineral Recovery

In addition to physical and chemical methods, several biotechnologies are currently being developed to extract valuable minerals from coal ash. For example, bioleaching is a targeted method for using microorganisms and their metabolites to solubilize desirable metals and enhance their extraction2. Biosorption is another biological extraction solution that is beneficial for recovering minerals from ores, tailings, and waste streams. Microbial processes like these can potentially be more economical, energy efficient, and environmentally friendly than highly engineered and solvent-heavy methods3.

If your research could benefit from Microbial Insights’ microbiology and biotechnology expertise, please contact us to explore how we can help advance your R&D goals. For over 30 years, Microbial Insights has been a trusted research and development partner to academia, government agencies, and the private sector. Our collaborations include the development of custom CENSUS® qPCR assays for specific client applications and utilizing our molecular biological tools to independently validate client products for promoting or controlling microbial activity. For example, the QuantArray®-BGC analysis quantifies 25 different microbial groups and can be used to assess the genetic potential for a variety of biogeochemical processes. Next Generation Sequencing provides comprehensive characterization of microbial communities and can be used to identify microorganisms when relevant qPCR assays are unavailable.

Contact info@microbe.com for more information or how we can help provide insightful data for your project.

1 Reedy RC, Scanlon BR, Bagdonas DA, Hower JC, James D, Kyle JR, Uhlman K. Coal ash resources and potential for rare earth element production in the United States. International Journal of Coal Science & Technology. 2024;11:74. https://doi.org/10.1007/s40789-024-00710-z.

2 Ma J, Li S, Wang J, Jiang S, Panchal B, Sun Y. Bioleaching rare earth elements from coal fly ash by Aspergillus niger. Fuel. 2023;354:129387. https://doi.org/10.1016/j.fuel.2023.129387.

3 Zurier HS, Banta S, Park DM, Reed DW, Werner AZ. Biotechnological solutions for critical mineral recovery from unconventional feedstocks. Current Opinion in Biotechnology. 2025;95:103336. https://doi.org/10.1016/j.copbio.2025.103336.

Image: Dan River coal ash spill - impoundment and power plant - 2014.jpg. (2024, December 29). Wikimedia Commons. Retrieved December 10, 2025, from https://w.wiki/Ga$K.