In the mining industry, strategies that leverage microbial processes are increasingly attractive as...

Produced Water, Critical Minerals, and Microbially Mediated Recovery

Mining companies are exploring microbially mediated processes such as bioleaching for critical mineral recovery. Meanwhile, energy companies are investigating oilfield produced water as a supply stream for critical minerals. At the intersection of these interests, biomining offers a transformative opportunity to extract high value critical minerals directly from oil and gas waste streams. This promising approach has the potential to generate economic value, improve wastewater treatment, and bolster supply chains for materials that power our future.

Understanding Produced Water as a Critical Mineral Resource

While each country defines its own list of critical minerals based on domestic priorities, a global race is underway to identify new sources of critical minerals that produce economic value and support the advanced technologies driving global development. While this can include prospecting for mineral deposits and developing new mines, there is growing interest in leveraging waste streams as a resource for critical minerals.

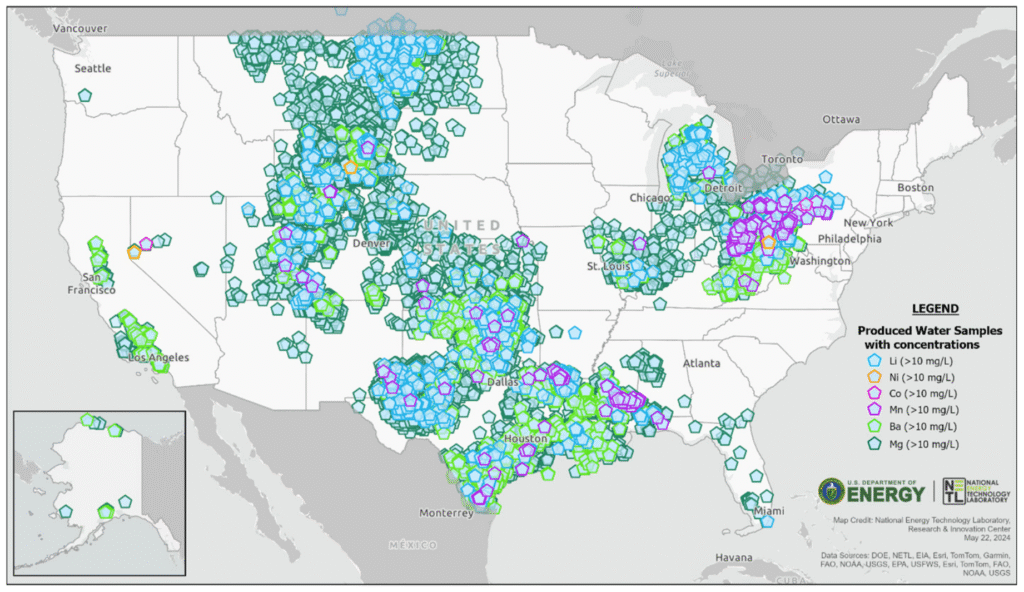

In the energy sector, produced water from oil and gas development operations has historically been considered waste. Produced water disposal is increasingly problematic both environmentally and economically, and it overlooks the recovery potential of critical minerals lingering in this waste product. The map below illustrates the critical minerals present in produced water from the United States’ petroleum reservoirs. Of the minerals identified by the United States Geological Survey (USGS) as critical, forty have been identified in produced water from the United States’ seven primary shale plays as of 20241.

Critical Mineral Concentrations in Produced Water. Source: US DOE, https://www.energy.gov/fecm/articles/fact-sheet-produced-water-oil-and-gas-development-and-critical-minerals

Energy, Technology, and Freshwater

Critical minerals are essential for the future of the energy industry and the advanced technologies that support modern society, but critical mineral recovery from produced water also supports the societal need for water decontamination and reuse. Even more than uranium, platinum, lithium, or praseodymium, freshwater is humanity’s most critical resource, and the volume of water produced from US oilfield operations can exceed 20 million barrels per day1.

Exercise: Lithium Recovery from Permian Produced Waters

In the US, lithium is considered critical due to its high value in the energy sector and supply chain risk. Significant concentrations of lithium have been identified in produced water. Multiplied by the sheer volume of water produced from oil and gas operations, this potential revenue stream is massive. For example, the United States Department of Energy estimates that over 15,500 metric tons of lithium could be recovered from the Permian Basin each year1. With an estimated price of $14,000 per metric ton of lithium2, the lithium recovered from Permian Basin produced water could yield over $217 million yearly. Importantly, this number is the value of lithium alone, and many other valuable metals and minerals are recoverable from produced water.

Mineral Recovery & Microorganisms

Microbiological processes can convert uneconomical waste into valuable resources. For decades, the mining industry has utilized microbial technologies such as bioleaching to extract metals like copper, gold, and uranium from low-grade ores. The comparatively low energy and solvent usage of bioleaching strategies make extraction from low quality resources profitable. Similarly, critical mineral recovery from waste streams like produced water has long been thought to be too costly, but research and investment into microbial methods are changing that equation.

Molecular biological tools can be employed to monitor and optimize the microbial consortia that facilitate primary ore processing, precision or multi-stage mineral recovery processes, water decontamination, and waste reuse. For example, the QuantArray®-BGC analysis quantifies over 20 different microbial groups and can be used to assess the genetic potential for metal precipitation. Next Generation Sequencing (NGS) is a DNA-based analysis that provides comprehensive characterization and identification of microbial communities. NGS data can be used to understand the relative concentrations of key genera across the site and over time or identify microorganisms when relevant qPCR assays are unavailable.

Looking to the Future

Microbial technologies are shaping the future of mineral recovery. Under the U.S. Department of Defense’s DARPA EMBER Program, Khoury et al. (2025) are isolating microbial proteins capable of selectively separating rare earth elements in solutions yielding high-purity products (up to 91%) without the need for traditional solvent extraction3. These proteins offer remarkable specificity, enabling single-phase separation processes that are cleaner, more efficient, and scalable.

As the demand for sustainable mineral recovery and produced water reuse grows, microbial solutions are emerging as a transformative force empowering stakeholders to optimize their processes with cost-effective, environmentally friendly methods. Microbial Insights can provide high-quality, high-resolution data driven insights into these microbial processes using molecular biological tools.

To discuss your project, reach out to Microbial Insights today at info@microbe.com.

1 Department of Energy Office of Fossil Energy and Carbon Management. Fact Sheet: Produced Water from Oil and Gas Development and Critical Minerals. Department of Energy. 2024. https://www.energy.gov/fecm/articles/fact-sheet-produced-water-oil-and-gas-development-and-critical-minerals.

2 U.S. Geological Survey. Mineral Commodity Summaries 2025 – Lithium Data Release (ver. 1.2, March 2025). U.S. Geological Survey. 2025;110. https://doi.org/10.3133/mcs2025.

3 Khoury FF, Heater BS, Marzolf DR, Abeyrathna S, Picking JW, Kumar P, Higgins SA, Jones R, Lewis AT, Kucharzyk KH, Banta S. Mining peptides for mining solutions: evaluation of calcium-binding peptides for rare earth element separations. Chemical Science. 2025;16:15333-46. https://doi.org/10.1039/D5SC02315G.